Carbon steel pipe flanges are integral components in various industrial applications, offering a reliable and secure connection between pipes and other fittings. These flanges come in a variety of types, each designed for specific functions and conditions. They are essential in industries such as oil and gas, chemical processing, power generation, water treatment, mining, food processing, and shipbuilding. In this article, we will explore the different types of carbon steel pipe flanges and their practical applications.

Image Source: Texas Flange

I. Introduction to Carbon Steel Pipe Flanges

Before we delve into the types and applications of carbon steel pipe flanges, it’s essential to understand the basics. Carbon steel flanges are made by incorporating carbon into iron, resulting in a material that boasts impressive strength and durability.

II. Types of Carbon Steel Pipe Flanges:

Carbon steel pipe flanges come in several types, each tailored to specific functions and conditions. Let’s explore these types in detail:

1. Weld Neck Flanges

- Weld neck flanges have a neck that extends from the flange’s base, providing a smooth transition between the flange and the pipe.

- Applications: Ideal for high-pressure and high-temperature applications, including oil and gas pipelines, power plants, and chemical processing.

Image Source: Texas Flange

2. Slip-On Flanges

- Slip-on flanges feature a 1/16″ lip and are designed to be slipped over the end of a pipe and then welded in place.

- Applications: Suited for pipe systems with low pressures and moderate temperatures. Commonly used in various industries.

Image Source: Texas Flange

3. Blind Flanges

- Blind flanges seal off the end of a piping system with no bore and are used to terminate a line or provide closure at the end of a pipe.

- Applications: Used to cover tube openings, valves, or tubing in various industrial settings.

Image Source: Texas Flange

Image Source: Texas Flange

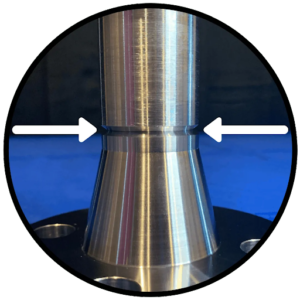

4. Socket Weld Flanges

Socket weld flanges are designed for welding onto the end of a pipe using a socket-weld joint. They have a tapered hub and a long tapered throat for high-pressure and high-temperature applications.

Applications: Suitable for applications that demand welds under pressure, such as power generation and chemical processing.

Image Source: Texas Flange

Threaded Flanges

- Threaded flanges have threads on both the inside and outside, allowing them to screw onto the end of a pipe.

- Applications: Used in low-pressure applications and are easily installed and removed.

Image Source: Texas Flange

III. Applications of Carbon Steel Pipe Flanges

The versatility of carbon steel pipe flanges makes them essential components in a wide range of industrial applications. Here are some industries and applications that rely on these flanges:

1. Oil and Gas

Carbon steel pipe flanges are commonly used in the oil and gas industry, as their strength and durability make them ideal for pipelines and other oil and gas applications.

2. Chemical Processing

Chemical processing plants require flanges that can handle corrosive fluids. Carbon steel pipe flanges, with proper corrosion protection, are suitable for connecting pipes in these harsh environments.

3. Power Generation

Power plants utilize carbon steel flanges to connect pipes in steam and water systems. Their high-temperature and high-pressure capabilities are well-suited for power generation applications.

4. Water Treatment

Flanges are used in water treatment plants to connect pipes in the water distribution system. The corrosion resistance of carbon steel flanges ensures longevity and reliability in these facilities.

5. Mining

In the mining industry, flanges are used to connect pipes in slurry and wastewater systems. The durability and strength of carbon steel flanges make them a practical choice in this demanding sector.

6. Food Processing

Food processing plants rely on flanges for connecting pipes in water and sanitation systems. The versatility of carbon steel flanges allows them to meet the stringent hygiene requirements of the food industry.

7. Shipbuilding

Flanges are essential in shipbuilding, where they connect pipes in ballast and bilge systems. Carbon steel flanges provide robust and reliable connections in maritime applications.

IV. Why Choose Carbon Steel Flanges Over Stainless Steel?

While stainless steel is a popular material for various applications, carbon steel flanges offer several advantages:

- Cost: Carbon steel is generally more cost-effective than stainless steel, making it a practical choice for projects with budget constraints.

- Strength: Carbon steel is stronger than stainless steel, making it suitable for high-pressure and high-temperature applications.

- Machinability: Carbon steel is easier to machine compared to stainless steel, facilitating faster manufacturing processes.

- Corrosion Resistance: Although stainless steel offers superior corrosion resistance, carbon steel flanges can be adequately protected against corrosion through coatings and protective measures.

FAQs (Frequently Asked Questions):

- What are carbon steel pipe flanges, and why are they used in various industries?

Carbon steel pipe flanges are components that connect and secure pipes and fittings. They are used in industries for their strength, durability, and ability to withstand high pressures and temperatures.

- How do weld neck flanges differ from slip-on flanges, and where are they commonly used?

Weld neck flanges have a neck extending from the base, making them ideal for high-pressure and high-temperature applications. Slip-on flanges, with a 1/16″ lip, are used in pipe systems with lower pressures and moderate temperatures.

- What is the primary function of blind flanges, and where can we find them in industrial settings?

Blind flanges seal the end of a piping system. They are used to cover tube openings, valves, or tubing in various industrial applications.

- In what situations are socket weld flanges used, and what benefits do they offer?

Socket weld flanges are employed for high-pressure and high-temperature applications. They offer a smooth transition from the flange to the pipe and are easy to install.

- What sets threaded flanges apart, and why are they used in specific applications?

Threaded flanges feature threads on the inside and outside and are suitable for low-pressure applications, such as those with atmospheric temperatures and elevated pressures.

- How do lap joint flanges differ from other flange types, and what makes them a practical choice for certain applications?

Lap joint flanges are used for larger-diameter piping systems, often requiring frequent assembly and dismantling. They have a unique two-component design with a stub end.

- Why is the oil and gas industry a significant user of carbon steel pipe flanges?

The oil and gas industry relies on carbon steel pipe flanges due to their strength, durability, and ability to withstand high pressure and temperature conditions in pipelines.

- Are carbon steel flanges suitable for corrosive environments, such as chemical processing plants?

Yes, with proper corrosion protection, carbon steel flanges can handle corrosive fluids, making them a practical choice for chemical processing applications.

- What advantages do carbon steel flanges offer in terms of cost, strength, and machinability when compared to stainless steel flanges?

Carbon steel flanges are generally more cost-effective, stronger, and easier to machine, making them suitable for high-pressure and high-temperature applications.

- How do you choose between carbon steel and stainless steel flanges for a specific project?

The choice depends on project requirements, including strength, corrosion resistance, and budget constraints. Carbon steel flanges are cost-effective, while stainless steel offers superior corrosion resistance.

- Are carbon steel flanges suitable for use in water treatment plants?

Yes, carbon steel flanges are used in water treatment plants to connect pipes in water distribution systems due to their corrosion resistance and reliability.

- What applications in the mining industry benefit from the use of carbon steel flanges?

In mining, carbon steel flanges are used to connect pipes in slurry and wastewater systems, thanks to their durability and strength.

- Can carbon steel flanges withstand the high pressures and temperatures found in power generation applications?

Yes, carbon steel flanges are ideal for power generation, connecting pipes in steam and water systems that experience high temperatures and pressures.

- What are the unique properties of socket weld flanges that make them suitable for high-pressure applications?

Socket weld flanges feature a tapered hub and a long tapered throat for a smooth transition from the flange to the pipe, making them ideal for high-pressure applications.

- What are the specific advantages of lap joint flanges, and where are they commonly used?

Lap joint flanges simplify the assembly and dismantling of large-diameter and stiff piping systems. They are a cost-effective choice for applications requiring frequent disassembly, such as low alloy steel piping systems.

Conclusion

Carbon steel pipe flanges are versatile components with different types tailored to specific applications. They are vital in industries such as oil and gas, chemical processing, power generation, water treatment, mining, food processing, and shipbuilding. The choice between carbon steel and stainless steel flanges depends on the specific requirements and constraints of each project, ensuring reliable and efficient connections in diverse industrial settings.

For further information and expert insights on Carbon Steel Pipe Flanges and related topics, feel free to explore these sites: