Carbon steel flanges are essential connecting components in piping systems across oil and gas, chemical processing, power generation, and industrial plumbing applications. Among the various carbon steel specifications, ASTM A105 and ASTM A106 are two of the most widely used and often confused materials. While both are carbon steel standards with similar chemical compositions, they serve distinctly different purposes in piping systems. ASTM A105 refers to forged carbon steel components used for flanges, fittings, and valves, whereas ASTM A106 specifies seamless carbon steel pipes for high-temperature service. Understanding the differences between these specifications is critical for engineers, procurement specialists, and fabricators to ensure system safety, compliance, and optimal performance.

This comprehensive guide provides detailed technical comparisons, application recommendations, and practical selection criteria to help you make informed decisions for your piping projects. We’ll explore the chemical compositions, mechanical properties, manufacturing processes, and temperature limitations that distinguish these two important carbon steel specifications, building on our previous discussion of carbon steel flange manufacturers to provide a complete understanding of carbon steel flange technology.

Table of Contents

Key Differences Between ASTM A105 and A106

While ASTM A105 and A106 share some similarities as carbon steel materials, they differ significantly in their intended applications, manufacturing processes, and performance characteristics. The table below summarizes the core distinctions between these two specifications:

Table: Key Differences Between ASTM A105 and A106 Specifications

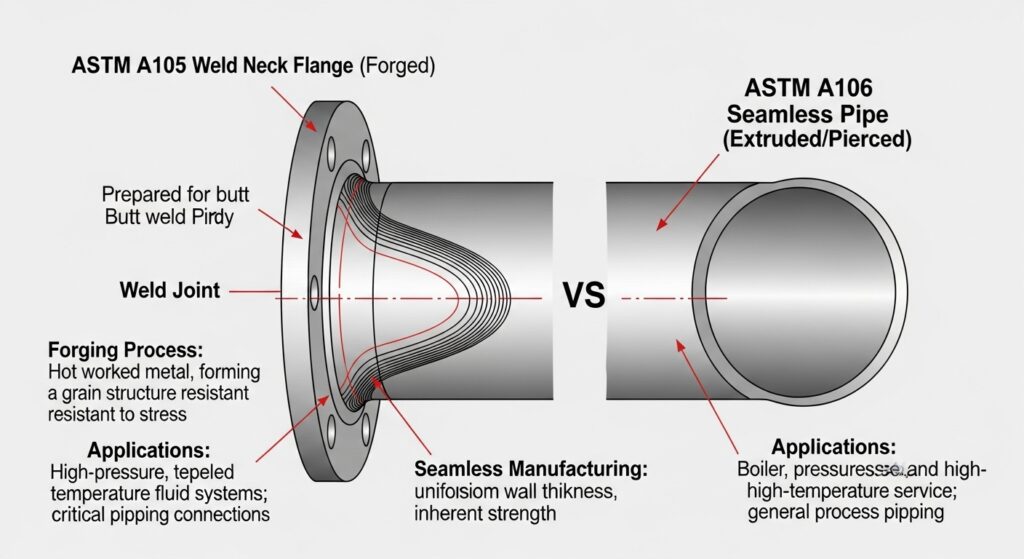

These fundamental differences stem from their intended purposes in piping systems. ASTM A105 is specifically designed for forged carbon steel piping components including flanges, fittings, and valves used in pressure systems at ambient and higher-temperature service conditions. In contrast, ASTM A106 covers seamless carbon steel pipe for high-temperature service, making it suitable for bending, flanging, and similar forming operations.

Technical Specifications: Chemical Composition and Mechanical Properties

The chemical composition and mechanical properties of A105 and A106 carbon steel directly influence their performance characteristics and suitable applications.

Chemical Composition Comparison

Both A105 and A106 are carbon steels with similar elemental compositions, but with varying percentages that affect their mechanical properties:

Table: Chemical Composition Comparison (Weight Percentage Maximum Unless Noted)

The slightly higher maximum carbon content in A105 (0.35% vs. 0.30% for A106 Grade B) contributes to its slightly higher tensile strength and yield point. The manganese content in A106 enhances its hardenability and strength, while the silicon content improves its resistance to oxidation at elevated temperatures.

Mechanical Properties Comparison

The mechanical properties of these materials determine their load-bearing capabilities and suitability for different service conditions:

Table: Mechanical Properties Comparison

The mechanical properties make A105 better suited for pressure containment applications where structural integrity under load is critical, while A106 offers better flexibility for piping systems that may experience thermal expansion, vibration, or other dynamic loads.

Applications and Industry Usage

The different properties of A105 and A106 make each material suitable for specific applications across various industries.

ASTM A105 Flange Applications

- Oil and Gas Equipment: Valves, wellhead components, and production manifolds

- Petrochemical Plants: Pressure vessel connections, reactor piping, and distillation columns

- Power Generation: Nuclear and fossil fuel power plant piping systems, boiler connections, and steam lines

- Marine Engineering: Shipboard piping systems, offshore platform components, and dock transfer lines

- Industrial Processing: High-pressure fluid transfer systems and compressor stations

ASTM A106 Pipe Applications

- Refinery Piping: Transfer lines for crude oil, intermediates, and finished products

- Power Plant Systems: High-temperature steam lines, boiler tubes, and feedwater piping

- Petrochemical Facilities: Process piping for chemicals at elevated temperatures and pressures

- Industrial Boilers: Heat exchanger tubes, furnace piping, and combustion systems

- Pipeline Systems: Transmission lines for oil, gas, and other commodities requiring seamless construction

Selection Guidelines: Choosing Between A105 and A106

Selecting the appropriate material specification requires careful consideration of your specific application requirements. Below are key factors to guide your decision-making process:

When to Choose ASTM A105

- For Flanges and Fittings: A105 is specifically designed for forged flanges, fittings, and valves

- High-Pressure Applications: Superior strength makes it ideal for pressure containment components

- Critical Service Conditions: Recommended for hazardous fluids where failure is not an option

- Wide Temperature Ranges: Suitable for applications from -29°C to 537°C (-20°F to 1000°F)

- Structural Integrity Requirements: Where dimensional stability under load is paramount

When to Choose ASTM A106

- Seamless Piping Systems: When requiring seamless pipe for high-temperature service

- Temperature Below 450°C: Optimal performance at elevated temperatures up to 450°C (842°F)

- Forming Operations: When pipes require bending, flanging, or other shaping processes

- Pressure Applications: For piping systems operating at high pressures

- Cost Considerations: When budget constraints favor A106 over A105 for appropriate applications

Material Selection Decision Framework

Consider the following questions when selecting between A105 and A106:

- What is the component type? (Flanges/fittings → A105; Pipe/tubing → A106)

- What are the temperature requirements? (Above 450°C → A105; Below 450°C → A106 acceptable)

- What are the pressure conditions? (Extreme pressure → A105; High pressure → A106 suitable)

- Is seamless construction required? (Yes → A106; No → Consider both options)

- What are the budget constraints? (Tighter budget → A106 may be more cost-effective)

Manufacturing Insights and Quality Considerations

Forging Process for A105 Flanges

The forging process used for ASTM A105 components involves shaping metal through compression forces, creating a superior grain structure that enhances mechanical properties. Forged flanges exhibit:

- Better structural uniformity with minimal irregularities

- Higher tensile strength compared to cast alternatives

- Improved grain flow that follows the contour of the part

- Reduced porosity and voids for enhanced integrity

- Superior performance in high-pressure applications

Seamless Manufacturing for A106 Pipes

ASTM A106 pipes are manufactured as seamless components through hot finishing or cold drawing processes:

- NPS 1-1/2″ and under: May be either hot finished or cold drawn

- NPS 2″ and larger: Typically hot finished unless otherwise specified

- Cold-drawn pipes: Require heat treatment after the final cold draw pass

- Hot-finished pipes: Generally do not require heat treatment

Rust Prevention and Corrosion Protection

Carbon steel components require protection against corrosion. Common methods include:

- Anti-rust painting: Creates a protective barrier against moisture and corrosion

- Oil varnishing: Provides lubrication and forms a protective barrier

- Electric zinc-coating (galvanizing): Thin zinc layer prevents water and oxygen from reaching the metal

- Alloy material coating: Cladding with corrosion-resistant alloys for severe environments

Frequently Asked Questions (FAQs)

Q: Can A105 flanges be used with A106 pipes?

Yes, A105 flanges are commonly used with A106 pipes in high-temperature piping systems. The materials have similar thermal expansion characteristics and are often specified together for refinery, power plant, and petrochemical applications. Ensure proper welding procedures are followed when joining these materials.

Q: What are the temperature limitations for A105 vs A106?

ASTM A105 can withstand temperatures from -29°C to 537°C (-20°F to 1000°F) , while ASTM A106 is typically recommended for temperatures below 450°C (842°F) . For low-temperature service, consider A350 LF2 material which is designed for cryogenic applications .

Q: Are there different grades within A105 and A106 specifications?

ASTM A105 is a single-grade specification for forged components. ASTM A106 includes three grades: Grade A (lowest strength), Grade B (intermediate strength, most common), and Grade C (highest strength) . Grade B is the most widely used across industries.

Q: Can A106 be used for flanges?

While A106 is primarily a pipe specification, it can be used for manufacturing certain flange types through further processing. However, for standard flanges, A105 is the preferred and code-compliant choice for pressure systems. Some specialty flanges may be machined from A106 pipe, but this is not common practice.

Q: How do I verify material certification for A105 and A106 components?

Request Material Test Reports (MTRs) from your supplier, which provide traceability to the original heat number and confirm chemical composition and mechanical properties. Reputable manufacturers like Texas Flange provide proper certification with their products .

Q: Which standard is more expensive, A105 or A106?

ASTM A105 components are generally more expensive than A106 pipes due to the forging process and additional machining required for flanges and fittings . However, the total installed cost should consider the specific application requirements rather than just material costs.

Q: Can A105 and A106 be used in corrosive environments?

Both materials have limited corrosion resistance compared to stainless steels. For mildly corrosive environments, protective coatings like galvanizing or paint systems are recommended . For highly corrosive services, consider stainless steel or alloy materials instead.

Conclusion

Choosing between ASTM A105 and A106 carbon steel specifications requires careful consideration of your specific application requirements. ASTM A105 is the clear choice for flanges, fittings, and valves requiring superior strength and pressure containment, while ASTM A106 is specifically designed for seamless pipes in high-temperature service. Understanding the technical differences in chemical composition, mechanical properties, temperature limitations, and manufacturing processes enables informed material selection for your piping systems.

For most flange applications, ASTM A105 provides the optimal combination of strength, durability, and temperature resistance. When sourcing these components, work with reputable manufacturers like Texas Flange who provide proper material certification and quality assurance. By applying the guidelines presented in this article, you can ensure the longevity, safety, and reliability of your piping infrastructure across various industrial applications.